What's Inside?

Antec's decision to team up with Delta to make its Signature PSU is unsurprising given Delta's heritage as one of the longest running and largest PSU manufacturers that mostly concentrates on server level power. In that respect there's a certain guarantee of quality since servers are built to be reliable, but we rarely see PSUs of this calibre permeate the consumer realm.

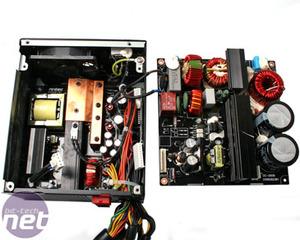

It's worth noting at this point the manufacturing quality is really very high - the soldering job is exceptionally neat, the PCBs are cleanly assembled and all the components are very solidly soldered or glued down, offering very little play.

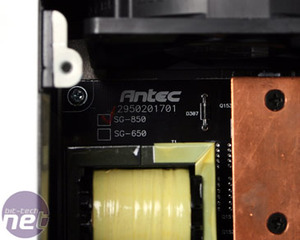

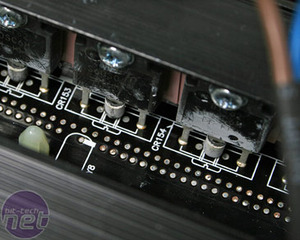

The same two PCB layouts are used for both 850W and 650W models as we can see above, although the component weighting is obviously different. Antec uses a two PCB design with a single 80mm fan made by Nidec - a huge Japanese manufacturer that builds motors for everything from PC fans to hard drive motors to vehicles and industrial applications. The D08A-12PS is an 8cm, sleeve bearing PWM controlled fan. The PWM control allows speeds from a full 2,400 RPM down to just 400 RPM to keep its noise to a minimum.

Inside we have the now standard DC-DC 12V conversion for 3.3V and 5V, as well as a dedicated 5V standby circuit too. With the two PCBs the design is largely spread out, allowing components breathing room, although only half the height to stretch into. This is offset by low profile heatsinks which are a ribbed along one side to increase surface area and direct the airflow from front to back. The extra space, Antec claims, affords less electrical interference and noise between components.

Antec also uses low profile, but very high quality pair of 105'C 450V Rubycon capacitors for the main stage power storage, then 105'C KZH capacitors, from Nippon Chemicon, elsewhere. There are no solid aluminium capped capacitors used in this design - Cooler Master used them for its fast response to smooth voltage ripple on the 12V connectors, while leaving a standard ferrite core for the 5V. Antec goes one better and includes ferrite rings for every major MOSFET instead.

This technique has also been replicated by the new Enermax Revolution and we were told during Computex this year this design is a pain to manufacture but gives better results than a general ferrite ring thrown over the top. In addition, on the conversion phases, especially for 3.3V and 5V, Antec uses tantalum surface mount and ceramic capacitors to reduce ripple and noise - tantalum caps are used on some high quality sound cards because of their fast response, long lifetime, high power to size ratio, high temperature tolerance and very low noise, but they are considerably more expensive than competing capacitors and obviously add to the price of the Signature.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.